Synchronization Solutions

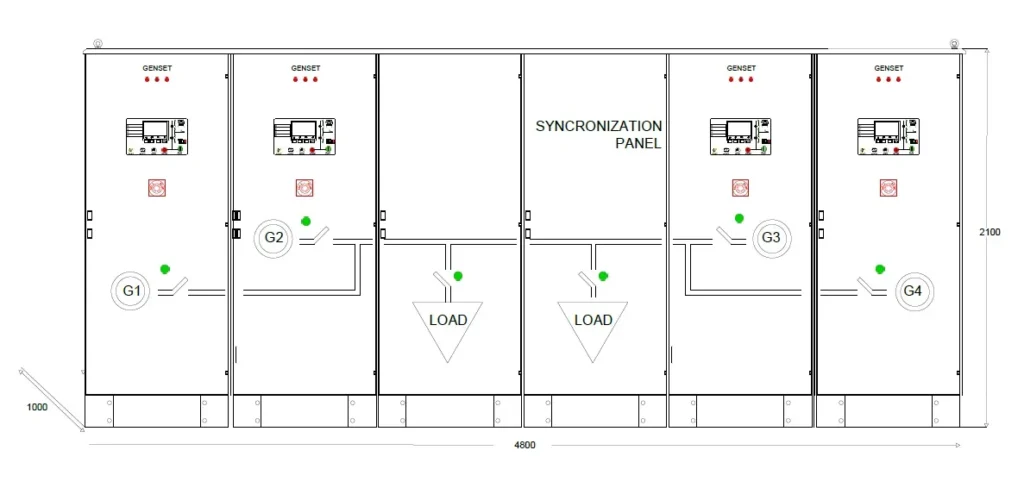

Ada Mode Generator Synchronization

The Inter-Generator synchronization system is called ADA mode system. The reason for this name is that there are receivers around the Generator Common Busbar. In this case, the generator common bus acts like an Energy Island with receivers around it.

The systems installed in these standards are not interested in grid energy information. It physically waits for a start command from the system on the Transfer Panel.

The generators in the system feed the field by starting all together according to the requirements of the field or by starting according to their priority values. Here, the start-stop functions of the generators are determined as a result of load analysis.

In this system, the operating priorities of the generator to be operated are physically determined by the user as well as by the generator operating hours.

From the moment the start signal is received, the master, i.e. the genset with the highest operating priority, starts. After reaching the nominal voltage and frequency value, it closes its switch to the common busbar. Other generators follow the parameters of the master generator over the communication line. When the necessary conditions are met, they perform the synchronization process by closing their own switches. After the synchronization process is completed, the field is fed through the generators via the transfer panel. From this point on, Reactive and Active load sharing starts between the generators according to the requirements of the system.

Grid Controlled Generator Synchronization

Seamless Soft Access System

Mains voltage and frequency values are controlled. When the mains energy goes out or goes out of limits, the control unit accepts the mains energy as passive. The grid switch opens. A start signal is sent to the generators over the communication network.

After the generators are synchronized to the common busbar, the genset common switch is closed by the control unit. The system is fed through the generators. When the grid energy arrives and is within the desired limits, the generators try to provide synchronization conditions with the grid. When the synchronization condition is met, the grid switch and generator switches are closed simultaneously and the load is gradually transferred to the grid via the generators. The generators enter the cooling period.

Short Interrupted Transition System

Mains voltage and frequency values are controlled. When the mains energy goes out or goes out of limits, the control unit accepts the mains energy as passive. The grid switch opens. A start signal is sent to the generators over the communication network.

After the generators are synchronized to the common busbar, the genset common switch is closed by the control unit. The system is fed through the generators. When the grid energy arrives and is within the desired limits, the control unit first opens the genset switch and then the grid switch is closed. The load is transferred to the grid via the generators. The generators enter the cooling period.

What is Synchronization in AC Diesel Generator Systems?

In AC diesel generator systems, the alternator output frequency value is adjusted by controlling the fuel control systems and the alternator output voltage value is adjusted by controlling the Voltage Control system. The controls of these points are controlled by a closed loop control system. With this control system, the responses of the diesel generator to the synchronization process are analyzed and appropriate parameters are selected. These parameters are of great importance for system reliability at the beginning of the synchronization process, during the synchronization process and at the end of the synchronization process.

In AC generator systems, the reference point of the synchronization process is always the energy point of the other system. Generators perform the synchronization process by adjusting their electrical parameters according to the reference point.

These points vary according to the configuration of the system.

A- Synchronization process between generators

The reference point in this system is the Generator Common Busbar. The energy in this busbar is analyzed and the Synchronization Control Unit of the Generator adjusts the parameter values.

B- Synchronization Process Between Generator and Grid

In such systems, the reference point is both the grid and the generator common bus. This point will vary as the forward-backward synchronization process will take place due to the system.

Why Choose a Synchronization System?

Maintenance – Repair Cost : When more than one generator is preferred instead of a single generator to meet the installed power, the maintenance period will extend the period of use. In addition, the cost in terms of time will decrease as the maintenance cost / time ratio will decrease.

System Backup and Reliability : In multiple generator applications, if one of the generators in the system fails or during the periodic maintenance period, the other generator(s) will be activated. The generators will work as back-up generators in terms of each other.

Synchronization in Functional Fields

Functional sites can include more than one grid, clamping switches that can be added to the load / generator / grid sides, MV synchronization with step-up transformers, fuel automation systems, 7-10 stage load shedding – receiving operations.

In functional sites, all equipment in the system is integrated by POWERBİR GENERATOR Engineering team.

The whole system can be associated with SCADA / HMI Operator Panel / PLC supported automation system within the field requirements. With this, field reliability, monitoring and controlling capacity is increased.

Some Terms in Synchronization Systems

What is Equal Aging?

Synchronization is trying to equalize the operating hours of the generators to be synchronized. The generator that will run from the moment the grid is cut in the field is the Master Generator. After the generators are synchronized, the site is fed and load analysis begins. As a result of this analysis, the number of generators that will meet the site load continues to feed the site. The remaining generators switch to the stop position at the end of the cooling period. The master generator is the generator with the least operating hours among the generators in the system. The first generator to start counting the cooling time is the generator with the highest operating hours.

This operation is called EQUAL AGING.

What is an Outage?

This application can be done if it is known when the grid energy will go. This application can be done in two ways.

Temporal determinable. If it is known at which time intervals the grid will go, the generators take the load from the grid before the grid is cut. If the grid arrives at the specified time, the generators deliver the load to the grid, if not, the site continues to be fed through the generator.

It can also be done physically. The user takes over the field with uninterrupted transfer from the grid by means of the switch on the POWERBİR Synchronization Panel or the button on the SCADA / OPERATOR PANEL. When the switch or the relevant input is passive, the site is transferred to the grid with uninterrupted transition.

What is Load Sharing?

In Multiple Generator Synchronization applications, generators share the field load in proportion to their power. This sharing is realized as Active and Reactive.

WHAT IS SYNCHRONIZATION?

Synchronization systems literally means matching and equalization. In AC electrical systems, there are some conditions for these pairings to be created.

01.

VOLTAGE RMS value of the phase to be matched

02.

FREQUENCY value of the phase to be matched

03.

WAVE FORMS of the phases to be matched

04.

Sequences of phases to be matched for 3-phase systems

05.

For 3-phase systems, DIFFERENCE IN PHASE ANGLE between each phase to be matched